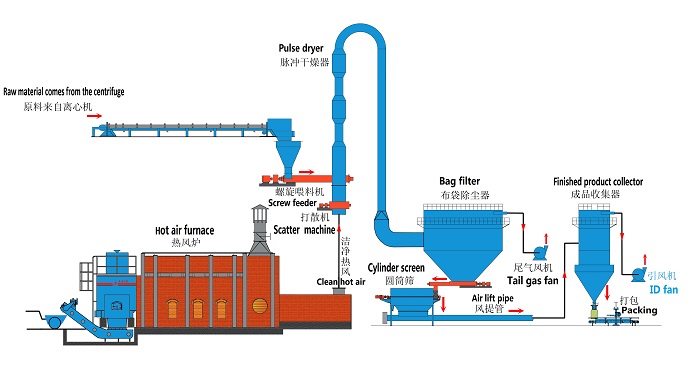

Drying System | Air Flow Dryer

The drying line is composed of wet material feeding system, hot air generating system, drying system, gas separation system, screening cooling system and so on. After the wet material is dispersed, it merges with the clean hot air generated by the hot air furnace, and a strong mass and heat transfer process takes place in the pulsed air dryer, and the material is quickly dried. After the dry materials are sieved, airlifted and rapidly cooled, they are stored in the finished product bin for storage and packaging. The exhaust gas is dedusted through the dust collector and the discharge is up to standard.

Technical characteristics:

(1) The pulse airflow dryer has the characteristics of large drying strength, high thermal efficiency, large processing capacity and low energy consumption;

(2) The system is operated under micro-negative pressure, the airtightness is very good and the work environment is smoke-free dust leakage;

(3) Mature and reliable control system to ensure the uniformity and stability of product quality;

(4) The system has strong operability, small footprint and low investment.